Tags Friction Feeding&Printing&Inspection System

With the development and progress of society, various anti-counterfeiting technologies have also developed rapidly, which has put forward higher requirements for the printing and packaging industry, especially for printing industries such as bills, drug packaging, and labels, which need to make sufficient efforts in printing technology. For example, anti-counterfeiting labels for many electronic products, wine packaging boxes, drug packaging boxes, invoices, etc. Digital anti-counterfeiting is the systematic management of databases, giving each ticket, card, product label, and even packaging box a unique identity during the printing process.

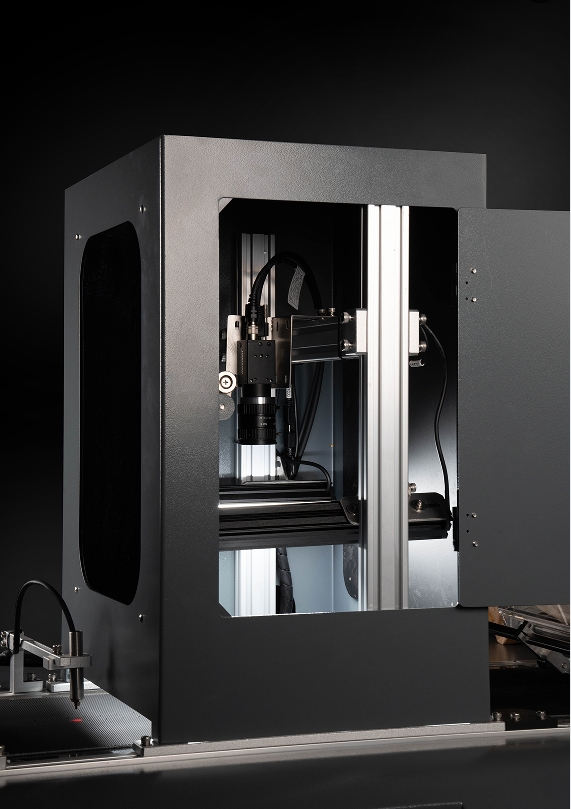

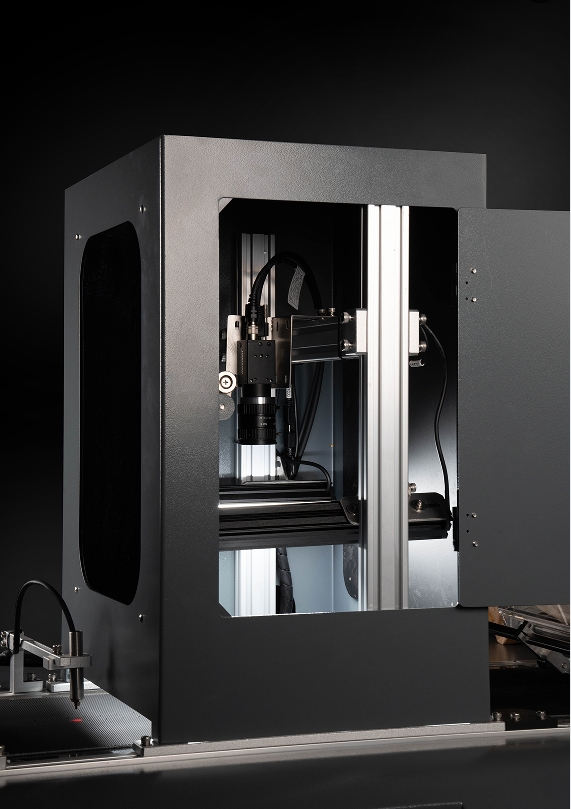

The single UV inkjet code verification and removal system is a system that solves the problem of variable information printing in the printing field. It has a wide range of applications in industries such as pharmaceutical packaging, bill printing, label printing, etc. This system is capable of printing variable barcodes, variable numbers and strings, variable images, as well as visual inspection systems.

Product Introduction

1.1 Technical specifications

Equipment parameters:

Equipment size: 3600mm * 1620mm * 1500mm (length * width * height)

Equipment weight: approximately 800KG

Power usage: AC220V/3KW

Basic functions of the device:

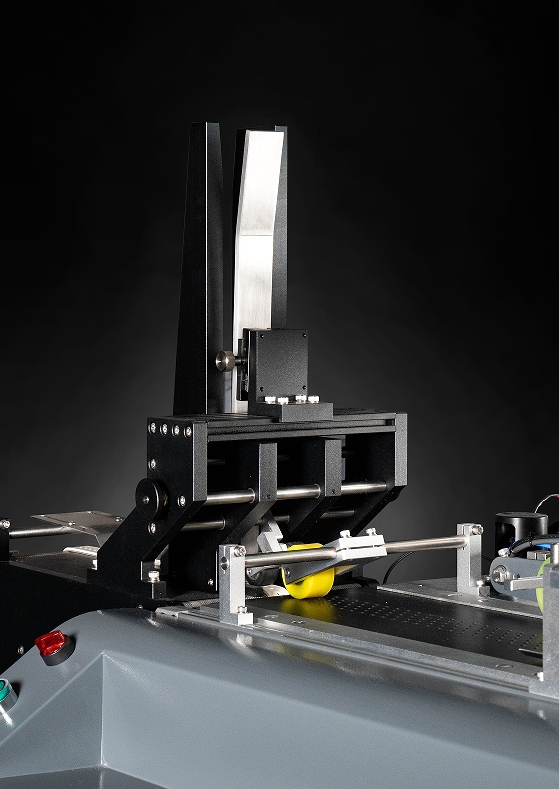

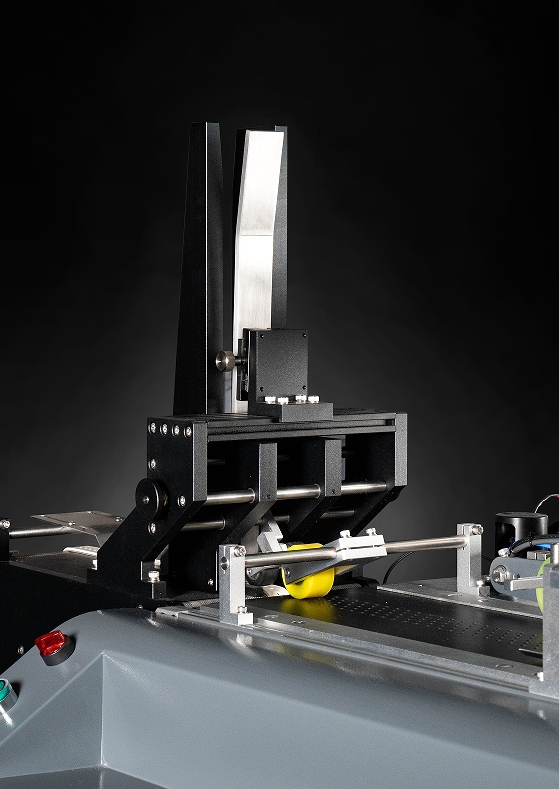

Film sending → UV coding → Visual inspection (optional) → Material receiving

Conveyor belt: negative pressure type

Air pressure: 0.5MPA

Suitable material: flat single sheet paper card

Paper card size: thickness 0.15-3MM, maximum width 150MM

Maximum operating speed: 0-80 meters per minute

Inkjet printer parameters:

Nozzle: Ricoh G5

Maximum printing size: printing width 54mm

Resolution: 600/dpi

Ink supply system: central ink supply system

Interfaces: serial port, Ethernet port, electric eye, encoder interface, print nozzle interface

Sensors: Supports multiple external sensors (NPN type, contact type)

Operating System: Windows10

Printing object:

Dynamic text, counter, date, dynamic barcode, static text, image (can be dynamic)

Barcode type: one-dimensional code (EAN28, Code25, Code39, Code93, Code128, GS1Databar, etc.)

QR codes (PDF417, DataMatrix, MaxiCode, QR Code, etc.)

Maintenance and upkeep of equipment

1. Before starting up, all debris on the machine should be cleared, especially near moving parts, and tools should not be placed

Items such as rags.

2. Operators must undergo training (especially safety training) before they can take up their posts.

When there is more than one operator of the machine, it should be stipulated that one person is responsible for starting the machine, and the rest of the personnel are not allowed to start it. Before starting the machine, the operator should observe whether there is anyone approaching the moving parts of the machine. Only when it is confirmed that all personnel will not touch the moving parts of the machine can it be started, and the other personnel should be reminded when starting the machine.

When the machine is running, if the operator (any one) discovers any abnormal situation, they should promptly press the emergency stop switch and inform other operators.

5. Unless necessary and with sufficient protective measures, no part of the body or object is allowed to come into contact with the moving parts of the machine.

6. Non operators must be notified in advance if they want to intervene in the adjustment, debugging, or testing operations of the machine.

7. Before turning on the power switch and powering it back on, it is necessary to ensure that the surrounding environment (including personnel, equipment, and transmission components) is in a safe state, otherwise the power cannot be turned on!!

When disassembling or cleaning the machine, the emergency stop switch must be pressed to avoid accidental operation, and any abnormal operation (including cleaning) is not allowed while the machine is running.

When it is necessary to maintain the machine for a long time, the main power should be turned off and a "Do not turn on" warning sign should be hung in a prominent place on the machine.

10. Without permission, it is not allowed to dismantle or change the parts on the machine, especially the safety protection parts, and the safety signs should be protected during operation.

When it is necessary to restart after maintenance, in addition to cleaning the site, the moving parts should be manually turned or operated to see if there are any obstacles.

When all operators leave the work area where the machine is located, the power should be turned off and locked to prevent unauthorized personnel from turning on the machine. Untrained and unqualified personnel are not allowed to operate the machine.