Paper Sheet Transport Variable Data Coding System

This machine could be widely used on sheet by sheet in fields of medical, food packaging, lottery, ticket, bill, note and cards with high efficiency and humanistic operation.

I. Basic parameters

Item | Name | Value | Unit |

1 | Model | VDGM-1040*1040,780*780,1060*1060 | |

2 | Applicable materials | White card, coated paper | |

3 | Materials Thickness | 70~450 | g/㎡ |

4 | Speed | ≤150 | M/MIN |

5 | Maximum paper feeding Length and Width | 1040*1040 780*780 1060*1060 | MM |

6 | Minimum paper feeding Length and Width |

400*400 |

MM |

7 | Overall dimension (L * w * h) | 12*2.00*2.1 | M |

8 | Total power | ≤14 | KW |

9 | Supply voltage | 380±5% | V |

10 | Air Pressure | ≥0.6 | Mpa |

11 | Machine Weight | 5800 | KG |

12 | Machine Color | White + Grey | |

13 | Speed | 100-150m/min | |

II.Function Description:

1. Correct the paper feeding error with a pull gauge ± 0.1mm.

2. The whole belt of the spray printing part is fully adsorbed.

3. The whole belt of LED part is fully adsorbed.

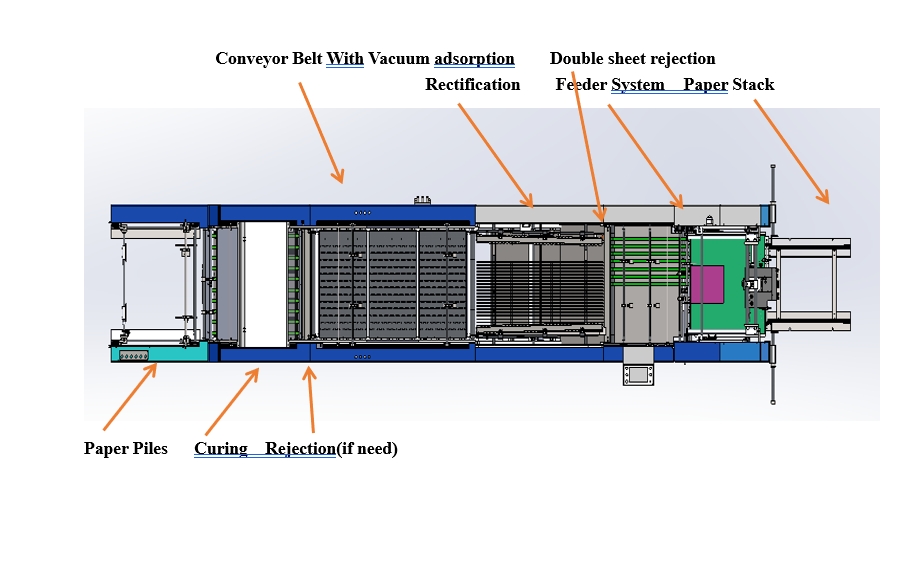

Paper feeding process:

III.Main structure:

1) . Paper conveying

The printing machine is used for four suction and four feeding and high speed Feder (the maximum speed is 13000 sheets/hour). The paper can be stacked up to about 3000 sheets at a time on a high platform, and the stacking height is 1200MM, greatly improving the working efficiency. The conveying part is equipped with a pressing wheel device, which makes the paper feeding more stable. Adopt ultrasonic wave to detect double sheets, and automatically alarm and shut down.

2) . Side gauge deviation correction

The elongated diagonal ball side gauge positioning structure is used for positioning during the paper operation, with the positioning accuracy of ± 0.1mm.

3) Spray code adsorption

High stability platform, the whole process suction synchronous belt conveying is adopted to make the paper conveying more stable,

4) Scraping part

Pneumatic flap waste removal device, which can be used in conjunction with the detection system to remove waste accurately and equipped with waste paper collection platform, can effectively reduce waste

5) . Fish scale paper receiving

After the paper is solidified, the fish scale superposition can reduce the paper speed and facilitate the paper receiving, especially for the thin paper, which has more advantages.

6) . Paper receiving section

The funnel-shaped paper receiving is combined with the vibrating motor to make the paper receiving more neat, and automatically drops according to the paper receiving capacity.

7) . Electrical control system

The four drives of paper conveying, side gauge correction, code spraying adsorption and fish scale paper receiving are all driven by servo motors, with high operation accuracy and stable operation. Different speeds can be set for each separate drive according to different requirements.

IV. Main configuration

Item | Type | Brand |

PLC | Taiwan Delta | |

Touch Screen | Taiwan Delta | |

Frequency converter | Taiwan Delta | |

Main motor | Taiwan SY | |

AC contactor Thermal relay Travel switch |

Chint Electric

| |

Switch | Schneider | |

Conveyor belt | Habers, Switzerland | |

Servo motor | Haide servo | |

Bearing | Japan NACHI bearing | |

Solenoid valve | Taiwan Yadeke | |

Power switch | Mingwei, Taiwan |